TUBULAR MOTOR ERBIL

DISCOVER THE BENEFITS

WHY IT MAKES SENSE FOR YOU

A Tubular makes your life more comfortable, and easy.

A tubular motor is an electric motor embedded in a cylindrical form factor. They are typically used for window shades and blinds, projection screens, awnings, roller doors, etc. Contact us to learn more about our tubular motors options.

CHOOSE SIMPLICITY

Switch to a tubular motor that responds to your commands.

MORE PRACTICAL

ALL IN A CLICK!

A tubular motor increases your property value, and makes your property more secure.

COMPLETE THE SYSTEM

FIND OUT HOW TO MAKE YOUR TUBULAR MOTOR UNIQUE AND SPECIAL

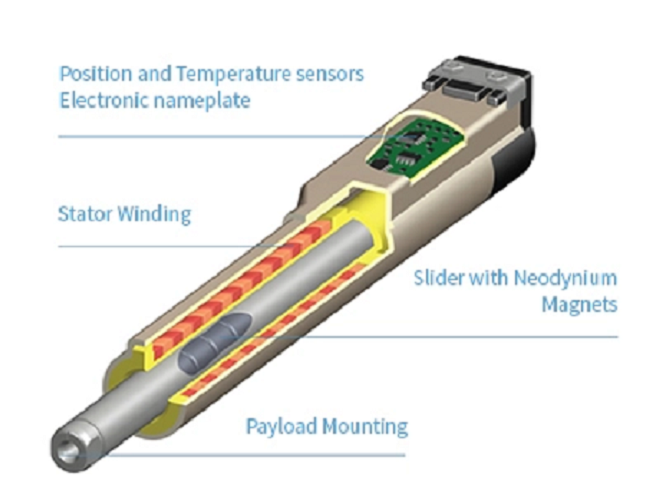

The tubular motor is a well-known means for the automated opening and closing of Venetian blinds, roller blinds and similar vertically hanging screens. Tubular motors for these purposes are typically required to provide torques of about 5-50 Nm, and are generally powered by the mains electricity, as supplied by the distribution network. They consist of a tubular housing, usually a metal tube having a circular or a polygonal cross-section, which is insertable into the spindle (roller) of a roller blind, the headrail of a Venetian blind, or some similar, unobtrusive location. The tube contains both the driving system and the winch mechanism for folding, winding or otherwise displacing the hanging screen to which they are coupled.

Tubular motors of the crowded prior art use either compact DC motors or asynchronic AC motors as the central element of their driving systems. When a tubular motor containing a DC motor is used, before it can be powered by an AC power supply, such as the mains, the supply current has to be rectified and transformed. Available transformers and rectifiers are too large to fit into the spindle or headrail of a blind, and a bulky, external power pack comprising these components is required, between the mains socket and the tube. Suitable power packs may be directly plugged into a mains outlet socket, but they are heavy, and have a tendency to pull the sockets out of the wall, or to damage their own pins. Alternatively, they may be wall-mounted under the spindle or headrail. Due to their bulk, these power packs are unaesthetic and generally awkward and inconvenient. On the other hand, AC motors, such as the common asynchronous cage-rotor type motors, do not require bulky rectifiers and transformers. However, to fit an AC motor of this type into a motors, do not require bulky rectifiers and transformers. However, to fit an AC motor of this type into a narrow tube, costly monofilament wires are required for its coils. Apart from being relatively expensive, small AC motors of this type have only very low efficiency rates, of around 4-6%, and warm up rapidly in use. To protect the coils of fine wire from overheating and burning up, a thermostat, or other protective device, is used to cut the current supply after only about 4 minutes of operation. Additionally, mains driven AC motors are powered by relatively high voltage electricity: 120 V in the United States and 240 V in the UK and elsewhere. To enable the dispersion of heat, the housing for such motors is generally required to be heat conductive, and in consequence, is electrically conductive. The proper earthing of such devices is critical.

Accordingly, there is a long felt need for a narrow tubular motor, suitable for mounting within the spindle or headrail of a blind, that can be connected straight to the mains electricity supply without requiring intermediate transforming / rectifying components mounted externally to the tubular motor housing. Preferably, such a tubular motor would have a relatively high efficiency rate, a low weight, and a simple construction, and would generally include, in addition to the driving system, a winch mechanism located within the housing.

Tubular motors of the crowded prior art use either compact DC motors or asynchronic AC motors as the central element of their driving systems. When a tubular motor containing a DC motor is used, before it can be powered by an AC power supply, such as the mains, the supply current has to be rectified and transformed. Available transformers and rectifiers are too large to fit into the spindle or headrail of a blind, and a bulky, external power pack comprising these components is required, between the mains socket and the tube. Suitable power packs may be directly plugged into a mains outlet socket, but they are heavy, and have a tendency to pull the sockets out of the wall, or to damage their own pins. Alternatively, they may be wall-mounted under the spindle or headrail. Due to their bulk, these power packs are unaesthetic and generally awkward and inconvenient. On the other hand, AC motors, such as the common asynchronous cage-rotor type motors, do not require bulky rectifiers and transformers. However, to fit an AC motor of this type into a motors, do not require bulky rectifiers and transformers. However, to fit an AC motor of this type into a narrow tube, costly monofilament wires are required for its coils. Apart from being relatively expensive, small AC motors of this type have only very low efficiency rates, of around 4-6%, and warm up rapidly in use. To protect the coils of fine wire from overheating and burning up, a thermostat, or other protective device, is used to cut the current supply after only about 4 minutes of operation. Additionally, mains driven AC motors are powered by relatively high voltage electricity: 120 V in the United States and 240 V in the UK and elsewhere. To enable the dispersion of heat, the housing for such motors is generally required to be heat conductive, and in consequence, is electrically conductive. The proper earthing of such devices is critical.

Accordingly, there is a long felt need for a narrow tubular motor, suitable for mounting within the spindle or headrail of a blind, that can be connected straight to the mains electricity supply without requiring intermediate transforming / rectifying components mounted externally to the tubular motor housing. Preferably, such a tubular motor would have a relatively high efficiency rate, a low weight, and a simple construction, and would generally include, in addition to the driving system, a winch mechanism located within the housing.